Plant the future with PLA

A 100% biobased plastic

Reducing our carbon footprint

The production of biobased Luminy® PLA has a 75% reduced carbon footprint, including biogenic carbon, compared to conventional plastics. Our peer reviewed LCA analyses contain a more detailed overview of the global warming potential and of how Luminy® PLA performs in other environmental impact categories such as carbon footprint, water footprint and direct land use change.

The sugarcane crops absorb carbon from the atmosphere while growing and store it in their biomass. It is called biogenic carbon. This carbon is then transferred to the value chain to end up in the PLA final product. When incinerating the PLA plastic product, this biogenic carbon will be released back into the atmosphere, making the process neutral.

The use of biobased bioplastics reduces our dependency on fossil fuels and supports a circular, local-for-local economy thanks to the multiple end-of-life options. Luminy® PLA is a certified 100% biobased polymer that can be used in many applications replacing conventional plastics.

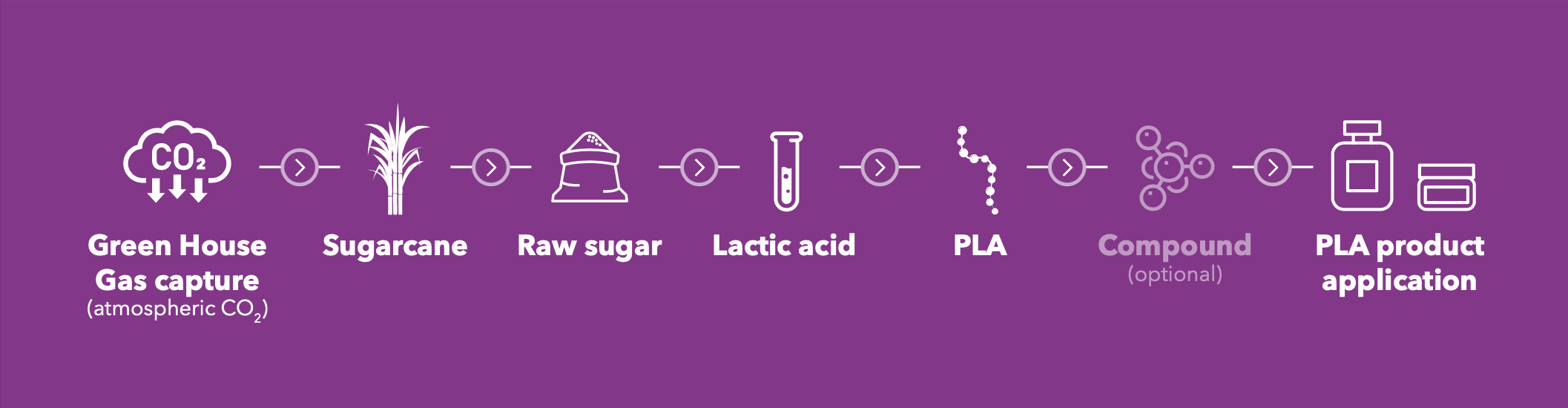

The biobased origin of PLA

Renewable feedstocks

Planting sugarcane is the starting point for Luminy® PLA production. After growing and harvesting the sugarcane, it is brought to a sugar mill to extract the sugar. The sugar obtained is then fermented using microorganisms to produce lactic acid, an organic acid also produced by the human body. TotalEnergies Corbion converts the lactic acid into PLA, a biopolymer that manufacturers can use in multiple applications from packaging to 3D printing to electronics.

Read the whitepaper

The whitepaper "Planting the future with PLA" has outlined many aspects related to feedstocks used for biobased bioplastics. Consumer awareness and interest in environmentally sustainable and ecologically sound products is increasing and continues to drive the demand for bioplastics. Importantly, we have shown that the overall total impact that the bioplastics market has on land use does not pose a threat to food production. Considering all the different angles, we conclude Luminy® PLA is a more sustainable and environmentally friendly alternative to traditional plastics.

EU Taxonomy

TotalEnergies Corbion Luminy® PLA produced in Thailand fully complies with the regulations of the EU Taxonomy Delegated Act, meaning that it qualifies as a sustainable material within the framework of reducing environmental impact and mitigating climate change in the region. For plastics users, this demonstrates that they can substantially reduce their Scope 3 GHG emissions by replacing fossil-based plastics with PLA.

Certifications

Luminy® PLA s certified 100% biobased according to EN16785 and USDA biopreferred program.

Unlike trees, for example, sugar cane used in the production of Luminy® PLA is an annually renewable crop. This means that the sugar cane harvest occurs every year, and new plants grow in the same land the following year.

Corbion, our lactic acid supplier, uses a code of conduct for all their cane sugar suppliers, as well as specific extensions directly relating to sugarcane farming in Thailand and Brazil. Verification procedures are in place to confirm that a supplier meets these requirements. These include tools such as self-assessment questionnaires, third-party verification and Bonsucro certification.

Luminy® rPLA, a powerful value proposition

Since 2021, TotalEnergies Corbion has been offering a version of its Luminy® PLA grades with recycled content. Collected post-industrial and post-consumer PLA waste are depolymerized via hydrolysis producing lactic acid. The lactic acid is then reprocessed in the polymerization line to produce new PLA. Thanks to this advanced recycling technology, the new recycled PLA grades are of the same quality as the virgin material.

Recycling biobased plastics multiplies the environmental benefits. In fact, changing the feedstock from crops to waste avoids all the impacts linked to agricultural activity. Using PLA waste as raw material reduces almost 100% the land use impact.

PLA's reduced global warming potential

The starting point for the Global Warming Potential of PLA is the CO2 absorption from the atmosphere by the growing sugarcane. According to the biomaterial storage approach, the amount of CO2 fixated in the PLA material is 1833 kg CO2/ ton of PLA.

Global net emissions from PLA production are 2334 kg CO2/ton of PLA which makes the carbon footprint of PLA production 501 kg CO2/ton PLA when deducting the carbon uptake. The biggest contributor to the GWP in the PLA production process is in the production of lactic acid. This is mainly due to the energy consumed and the chemical usage. The emissions from TotalEnergies Corbion's PLA plant arise from natural gas and energy consumption.

The GWP of the sugar cane production is influenced by fertilizer usage, the plant burning, and the fuel used in machines and equipment. Finally, the sugar mill impact is negative due to the highest gain from heat and electricity produced from by-products.

Contact us!

Many of the world's largest consumer brands have begun their transition to bioplastics. Have you?